Roots Blowers and Vacuum Pumps: Essential Tools for Plastic Compound Manufacturing

Introduction

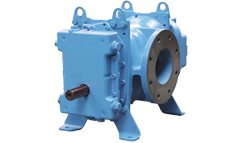

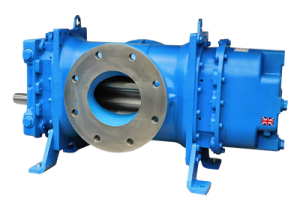

In the dynamic world of plastic and plastic compound manufacturing, the use of HR blowers range of roots blowers and vacuum pumps is paramount. These vital components not only enhance operational efficiency but also ensure the quality and purity of the final products. This article delves into the benefits and applications of these technologies, highlighting their indispensable roles in the industry.

Benefits of HR Blowers, Roots Blowers, and Vacuum Pumps

-

Enhanced Product Quality

• Contamination Prevention: Roots type positive displacement blowers are instrumental in pneumatic conveying, significantly reducing the risk of contamination. This is crucial in maintaining the integrity of plastic pellets and powders.

Product Integrity: By minimising degradation during transportation, these blowers ensure that the physical properties of materials remain consistent, leading to superior product quality. -

Operational Efficiency

• Reliable Performance: HR blowers supplied roots blowers are known for their robust and reliable performance, capable of handling the demanding needs of plastic manufacturing processes.

• Energy Efficiency: Our blowers are designed to optimise energy consumption, contributing to lower operational costs and a reduced environmental footprint. -

Versatility and Flexibility

• Multiple Applications: From conveying plastic pellets to powder transportation, our range of blowers and vacuum pumps offer versatile solutions for various stages of the manufacturing process.

• Adaptability: They can be configured for both vacuum and pressure modes, providing flexibility in handling different types of materials and processing requirements.

Key Applications in Plastic and Plastic Compound Manufacturing

-

Pneumatic Conveying

• Plastic Pellets: HR blowers Roots blowers are widely used globally to convey plastic pellets efficiently, ensuring a continuous and contaminant-free supply to molding machines.

• Powder Transportation: In the production of plastic compounds, these blowers facilitate the smooth and clean transport of powders, maintaining product quality and consistency. -

Vacuum Forming and Molding

• Vacuum Pumps: Essential in vacuum forming processes, these pumps create the necessary vacuum environment for shaping plastic sheets into desired forms with precision.

• Injection Molding: Vacuum pumps assist in removing air pockets and ensuring uniform material distribution during injection molding, resulting in defect-free products. -

Extrusion Processes

• Material Feeding: Industrial roots blowers play a critical role in feeding plastic materials into extrusion machines, ensuring a steady and controlled flow that is vital for high-quality extrusion.

• Degassing: Vacuum pumps are used to remove gases and volatile components during the extrusion process, improving the strength and appearance of the final product.

Types of Blowers and Pumps Used in the Industry

-

Roots Blowers

• Positive Displacement Technology: Utilising positive displacement, Roots blowers offer precise control over material conveyance, crucial for maintaining consistency in manufacturing.

• Versatile Applications: From vacuum to pressure applications, Roots blowers are adaptable to a wide range of industrial needs. -

Vacuum Pumps

• Efficient Air Removal: Vacuum pumps are essential for creating and maintaining vacuum conditions in various manufacturing processes, ensuring high product quality.

• Durability: These pumps are built to withstand the rigors of industrial use, offering reliable performance over extended periods.

Conclusion

The integration of HR Blowers UK’s roots blowers and vacuum pumps in plastic and plastic compound manufacturing processes is a game-changer. These technologies not only ensure high product quality by preventing contamination and degradation but also enhance operational efficiency and versatility. By understanding and leveraging these benefits, manufacturers can achieve superior outcomes, maintaining their competitive edge in the market.