Enhancing Cereal Plant Operations with HR Blowers Roots Blowers and Vacuum Pumps

Introduction

In the competitive world of cereal manufacturing, maintaining efficiency, hygiene, and product quality is paramount. HR Blowers UK roots blowers and vacuum pumps play a vital role in achieving these goals. This article explores the benefits and applications of these advanced technologies in cereal plants, highlighting their impact on various stages of the manufacturing process.

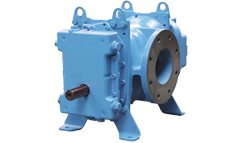

The Role of HR Blowers Roots Blowers in Cereal Plants

HR Blowers UK roots blowers are integral to several critical processes in cereal manufacturing. Here’s how they contribute to the industry:

- Pneumatic Conveying of Raw Materials: Roots blowers are essential in the pneumatic conveying systems used to transfer powder and granular materials such as grain, spices, chocolate, and milk powder. This method ensures hygienic, contamination-free transport, preserving the quality and integrity of the ingredients.

- Consistent Air Supply: These blowers provide a steady and controlled air flow necessary for various cereal manufacturing processes, including mixing and blending. Consistent air supply ensures uniformity and high product quality.

- Energy Efficiency: Designed for optimal performance, roots blowers consume less energy, contributing to lower operational costs and a reduced environmental footprint.

- Durability and Reliability: With robust construction, HR Blowers’ roots blowers are built to withstand the demanding conditions of cereal manufacturing, offering long-term reliability and minimizing downtime.

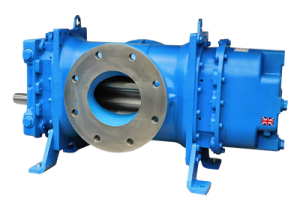

The Role of HR Blowers Vacuum Pumps in Cereal Plants

Vacuum pumps from HR Blowers UK are equally crucial in cereal manufacturing, particularly in packaging and material handling. Their benefits include:

- Efficient Packaging: Vacuum pumps are used to operate packaging machines, ensuring that cereal products are securely and hygienically packaged. This is vital for maintaining product freshness and extending shelf life.

- Material Handling: These pumps assist in the precise handling and transfer of sensitive ingredients, preventing contamination and ensuring consistent quality across batches.

- Operational Efficiency: With advanced technology and robust performance, HR Blowers’ vacuum pumps enhance operational efficiency, reduce maintenance needs, and ensure continuous, uninterrupted production.

Applications of HR Blowers Technologies in Cereal Plants

- Pneumatic Conveying Systems: HR Blowers’ roots blowers are used to pneumatically convey raw materials such as grains, spices, chocolate, and milk powder. This ensures efficient, contamination-free transport throughout the manufacturing process.

- Mixing and Blending: Positive displacement blowers provide the necessary airflow for mixing and blending ingredients, ensuring uniform distribution and consistency in the final product.

- Packaging Processes: Vacuum pumps play a crucial role in packaging by providing the necessary vacuum pressure to seal packages effectively. This ensures that cereal products remain fresh and safe for consumption.

- Material Transfer and Handling: Vacuum pumps facilitate the precise handling and transfer of materials, ensuring smooth and efficient movement of ingredients and preventing contamination.

Conclusion

HR Blowers UK roots blowers and vacuum pumps are indispensable in the cereal manufacturing industry. From ensuring hygienic pneumatic conveying and efficient mixing to facilitating secure packaging and precise material handling, these technologies enhance the quality, efficiency, and sustainability of cereal production. By integrating HR Blowers’ solutions, cereal manufacturers can achieve higher standards of production and meet the demanding requirements of the food processing industry.