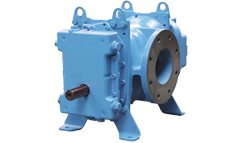

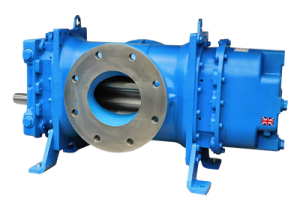

Enhancing Efficiency in Paper Mills with HR Blowers’ Roots Blowers and Vacuum Pumps

In the realm of global paper manufacturing, the utilisation of HR Blowers’ Roots blowers and vacuum pumps plays a pivotal role in enhancing operational efficiency and productivity across various processes. Our specialised equipment is integral for pneumatic conveying of wood pulp and other raw materials crucial for paper production. Additionally, they are instrumental in the drying stages by effectively removing water from the paper film, ensuring high-quality output.

Applications in Paper Mills

- Pneumatic Conveying: Roots blowers are extensively used for pneumatic conveying of wood pulp within paper mills. This process involves the transportation of materials through pipelines using air pressure generated by the blowers. By maintaining a consistent and reliable airflow, Roots blowers ensure smooth material handling, thus optimizing production efficiency.

- Water Removal in Drying Processes: During the paper drying process, efficient water removal is essential to maintain product integrity and reduce drying time. Roots blowers facilitate this by creating a vacuum that helps in extracting moisture from the paper web. This application not only accelerates the drying process but also contributes to energy savings and improved paper quality.

- Wastewater Treatment Systems: Paper mills typically have extensive wastewater treatment systems to manage and treat processed water and organic waste. HR Blowers’ vacuum pumps are employed in these systems to aid in the decontamination process. By creating the necessary vacuum conditions, these pumps facilitate the separation of contaminants and the extraction of moisture, thereby supporting efficient wastewater treatment and environmental compliance.

- Other Applications: Beyond the primary functions mentioned, Roots blowers and vacuum pumps are also utilized in various auxiliary processes within paper mills. These include air flotation systems for effluent treatment, aeration systems for biological treatment processes, and vacuum hold-down systems in paper converting and printing operations.

Benefits of HR Blowers’ Supplied Roots Blowers and Vacuum Pumps

- Reliability: Engineered for robust performance, HR Blowers’ products ensure continuous operation even under demanding conditions, minimising downtime in paper mill operations.

- Energy Efficiency: By optimising airflow and vacuum generation, these blowers and pumps contribute to significant energy savings, aligning with sustainable practices in paper manufacturing.

- Quality Assurance: Improved process control and consistent performance enhance the overall quality of paper products, meeting stringent industry standards and customer expectations.

In conclusion, HR Blowers’ Roots blowers and vacuum pumps are indispensable assets in modern paper mills, offering multifaceted benefits from enhancing efficiency in material handling and drying processes to supporting comprehensive wastewater treatment systems. As paper manufacturing continues to evolve, these advanced technologies remain pivotal in driving operational excellence and sustainability.

By integrating HR Blowers’ innovative solutions, paper mills can achieve operational efficiencies, reduce environmental footprint, and maintain a competitive edge in the global market.