Maximising Efficiency in Plaster Manufacturing with HR Blowers UK’s Roots Blowers and Vacuum Pumps

The Benefits and Usages of Roots Blowers and Vacuum Pumps in Plaster Manufacturing

Plaster manufacturing is a complex process that demands precision and efficiency. Among the essential equipment used in this industry are HR blowers globally supplied roots blowers and vacuum pumps. These tools are pivotal in ensuring the smooth handling, conveying, and processing of gypsum, a key ingredient in plaster. This article will delve into the benefits and diverse applications of these technologies in plaster manufacturing, offering insights into how they enhance productivity and quality.

The Role of Blowers in Plaster Manufacturing

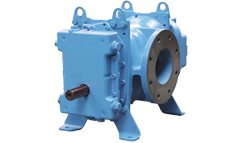

Roots type blowers also known as high-pressure blowers, are indispensable in plaster manufacturing. They facilitate the pneumatic conveying of gypsum, ensuring consistent and efficient material flow. These blowers operate at high pressure, which is crucial for moving gypsum through the manufacturing process without blockages. Their robust design and reliability make them ideal for the continuous operation required in plaster production.

Key Benefits of HR Blowers UK’s Roots Blowers:

- Enhanced Efficiency: HR blowers ensure the smooth and continuous movement of gypsum, reducing downtime and increasing production efficiency.

- Durability: Built to withstand the rigors of industrial environments, HR blowers offer long-term reliability and reduced maintenance costs.

- Precision: These blowers provide precise control over airflow and pressure, ensuring the consistent quality of the plaster.

The Importance of Roots Blowers in Plaster Manufacturing

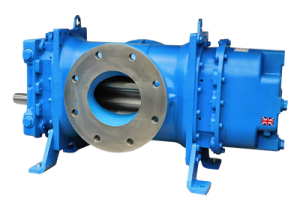

Roots Blowers are a type of positive displacement blower, renowned for their ability to move large volumes of air at low pressure. In plaster manufacturing, Roots blowers are used for both vacuum and pressure modes to pneumatically convey gypsum. This method significantly reduces the risk of cross-contamination, a critical factor in maintaining the purity and quality of plaster products.

Key Benefits of Roots Blowers:

- Versatility: Roots blowers can operate in both pressure and vacuum modes, making them versatile tools for various stages of the manufacturing process.

- Contamination Prevention: By enabling pneumatic conveying, Roots blowers minimize the risk of gypsum contamination, ensuring high-quality end products.

- Energy Efficiency: These blowers are designed to operate efficiently, consuming less energy and reducing operational costs.

The Significance of Vacuum Pumps in Plaster Manufacturing

Vacuum Pumps play a crucial role in the plaster manufacturing process by creating a vacuum environment that aids in the precise handling and processing of gypsum. These pumps are essential in applications such as gypsum dehydration, where they help remove moisture, ensuring the gypsum is at the optimal consistency for plaster production.

Key Benefits of Vacuum Pumps:

- Moisture Control: Vacuum pumps effectively remove excess moisture from gypsum, enhancing the quality and consistency of the plaster.

- Process Optimization: By creating a controlled vacuum environment, these pumps streamline various manufacturing processes, leading to improved efficiency.

- Quality Assurance: The precise control over pressure and vacuum conditions ensures that the final plaster product meets stringent quality standards.

Applications of HR Blowers supplied Roots Blowers and Vacuum Pumps in Plaster Manufacturing

- Pneumatic Conveying: Our Roots blowers are used to pneumatically convey gypsum, reducing manual handling and increasing efficiency. This application is crucial in both the initial processing stages and during the transportation of gypsum within the manufacturing facility.

- Gypsum Dehydration: Our vacuum pumps are employed to remove moisture from gypsum, ensuring it is ready for the plaster manufacturing process. This step is essential for achieving the desired consistency and quality of the final product.

- Dust Collection: Both our blowers and vacuum pumps are used in dust collection systems to maintain a clean and safe working environment. This application helps in minimizing health risks and ensuring compliance with environmental regulations.

- Packaging and Loading: HR Blowers UK vacuum pumps assist in the packaging and loading of plaster products, ensuring they are securely and efficiently prepared for distribution. This application enhances the overall productivity and reduces the risk of product damage.

By leveraging the benefits of our range of roots blowers and vacuum pumps, plaster manufacturers can significantly enhance their production processes, ensuring high-quality products and improved operational efficiency. These technologies are integral to modern plaster manufacturing, providing solutions that meet the industry’s stringent demands.